Description

In the field there is a frequent need to measure sensor readings rapidly and easily right at the sensor and to transfer them directly to a PC without additional amplifiers or converters. The 9206 USB sensor interface can satisfy this requirement admirably, thanks to its „plug & measure“ design. The USB connection means installation could not be simpler.

Typical applications:

Ready Player One is a 2018 film based on the 2011 novel of the same name by Ernest Cline. Directed by Steven Spielberg, from a screenplay co-written by Cline, the film was released on March 29, 2018. In the year 2045, overpopulation has forced. Not all devices can change this setting, and those that can vary in what values they support. Typical values for type are 10base2 (thin Ethernet), 10baseT (twisted-pair 10Mbps Ethernet), AUI (external transceiver) and so on. The special medium type of auto can be used to tell the driver to auto-sense the media. Again, not all drivers can do this.

- Mobile test measurements via laptop

- Laboratory test set-ups

- Instrumentation and control

- Diagnostic measurements in the chemical industry

- PC-based recording of expansion figures in bio engineering

The USB sensor interface takes its supply from the connected PC via the USB port, and uses it to generate the power supply for the sensors. The initial settings and sensor settings are made by burster in-house and saved in the USB sensor interface. These can then be fine-tuned by the customer.

Software provides display and archiving functions. But a license key enables an open-end expansion. 32 interfaces output curves may be displayed at the same time. One USB sensor interface can be connected as standard. Each sensor can be tared individually, and measurement curves can be displayed jointly or separately in a graph. We can configure the interface to suit a specific sensor, although customer-specific parameters can be changed using the free analysis software supplied.

The connection to LabVIEW or the integration into customers’ software is enabled by a free driver package.

Description

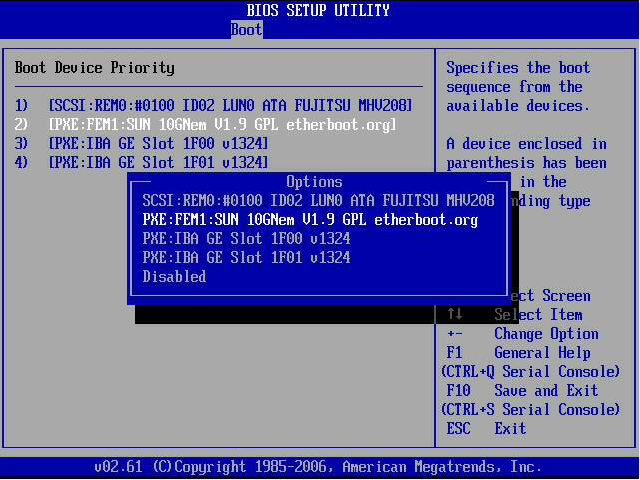

Burster Port Devices Driver

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques.

Burster Port Devices Driver Updater

An optional built-in incremental encoder disk with up to 2000 increments makes the sensor the perfect alternative where space or budget rule out an additional angle or speed sensor. For mobile use and for instant digital access to measurement data, the 8661 torque sensor is also available with a USB interface. A laptop or PC running the DigiVision PC software can read, visualize and archive the measurement data. System integration, for instance into LabView, is easy thanks to a driver package available free of charge.

► Test setups for precision mechanics

► Haptics testing of actuator elements

► Engine test benches and power measurement

► Biomechanical product testing

► Measurement of bearing friction torques

► Suitable for use in all types of test bench

Burster Port Devices Driver Bits

The 8661 torque sensor essentially consists of three blocks: the rotor, the housing (containing the stator) and the output electronics. The rotor is composed of several parts and contains the actual measuring device - a spring element. This spring element is designed to deform elastically under an applied torque. This results in torsion, which in turn pro-duces a very small amount of strain in the material of the measuring element. Within certain limits, this strain is linear and proportional to the applied torque. It can be measured using strain gauges, which are connected in a Wheatstone bridge circuit. A microprocessor conditions the signal from the Wheatstone bridge and transfers it to the stator. The rotor is linked to the stator via two ball-bearings, and signal transfer is contactless. The stator contains the electronics needed to supply the rotor with the required operating voltage by inductive and contactless means. In the opposite direction, it receives the optically transmitted, digitized torque signal and routes this signal to the output electronics. Here it is converted into an analog 0…± 10 V output signal, which is output via the connector. Alternatively, the sensor is available with a USB port. The 8661 torque sensor can optionally be fitted with an incremental encoder disk for measuring the speed and angle. This disk has 2000 increments, allowing angular resolutions of up to 0.045° by means of four-edge decoding. Three LEDs indicate the sensor operating status for simple diagnostics. Speeds of up to 25,000 min-1 can be measured depending on the selected measurement range and optional incremental encoder disk.